UNTIED EXPANSION JOINTS

- The Expansion Joints free to travel along its axis.

- Pressure Thrust Load will act on anchors.

- Anchors to be designed for both pressure thrust load and spring forces.

UNTIED - SINGLE EXPANSION JOINTS

- Simplest form of an Expansion Joint.

- Compensate Axial, Lateral and Angular movements - individually or combined of small magnitude.

- The Single Expansion Joint is usually considered as first option for any application since it offers lowest Expansion Joint cost.

UNTIED UNIVERSAL EXPANSION JOINTS

- A pair of Bellows connected with a Centre Spool.

- Compensate large amount of Axial, Lateral and Angular movements - individually or combined.

TIED EXPANSION JOINTS

- The Expansion Joints are restrained to travel along their axis (exception – pressure balanced types).

- Pressure Thrust Load is contained within the Expansion Joint.

- Pressure thrust load need not to be considered for anchor design.

TIED SINGLE EXPANSION JOINTS

- A Single Expansion Joint installed with Tie Rods.

- Compensate only Lateral Movement of smaller magnitude.

TIED UNIVERSAL EXPANSION JOINT

- A pair of Bellows connected with a Centre Spool.

- Compensate large amount of Axial, Lateral and Angular movements – individually or combined.

HINGED EXPANSION JOINT

- The construction of a Single Hinged Joint consists of a pair of hinges connected by a hinge pin.

- These hinges are designed to restrain the pressure thrust load and other external loads such as dead weight and wind.

- Single Hinged Expansion Joints are used, to absorb angular movement when the movement occurs in one plane only.

GIMBAL EXPANSION JOINT

- The construction of a Gimbal Expansion Joint incorporates a pair of hinges connected to a common floating Gimbal Ring.

- The Hinges & Gimbal Ring are designed to restrain the pressure thrust load and other external loads such as dead weight and wind.

- A Single Gimbal Expansion Joint is intended to compensate angular rotation in all directions.

PRESSURE BALANCED EXPANSION JOINT – ELBOW

A Pressure balanced Expansion Joint is capable of compensating axial and / or lateral movement and at the same time to contain the pressure thrust load within the Expansion Joint Assembly

This is achieved by tie rod restraints which connects the Line Bellows and an Opposite Balancing Bellows subjected to the line pressure

This type of Expansion Joint can be used only at a change in direction of pipeline.

INLINE PRESSURE BALANCED EXPANSION JOINT

In this assembly a Line Bellows is tied with the Balancing Bellows having twice the Effective area.

Due to tie arrangement, when the line Bellows is getting compressed to compensate the Pipe Expansion, the balancing Bellows will extend the equal amount, thus the volume across the Expansion Joint is maintained, hence no pressure thrust load

Inline Pressure Balanced Expansion Joints are used in straight pipe between two anchors to compensate the axial pipe growth, at the same time not to transfer the pressure thrust load to anchors.

They can accommodate small amount of lateral movement also.

SPECIAL TYPES

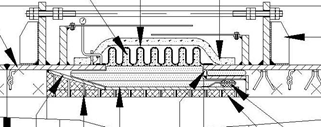

EXTERNALLY PRESSURIZED EXPANSION JOINTS

There are certain applications where a huge amount of axial movement has to be compensated.

An internally pressurized Expansion Joints with more number of convolutions to compensate the required axial movement is totally unstable even under small pressure.

Externally Pressurized Expansion Joint, in which the flow medium pressure is guided external to the Bellows, is an ideal solution to compensate huge axial movement.

Since the Bellows inside is subjected to only atmospheric pressure, there is no instability or squirm.

REDUNDANT PLY DESIGN BELLOWS EXPANSION JOINTS

- 2 – Ply Construction.

- Each ply designed to withstand the Design / Operating conditions.

- If one ply fails, the other ply will take its place until a scheduled replacement.

DOG BONE EXPANSION JOINTS

LSI-Mech Engineers Pvt. Ltd.’ Dog Bone Expansion joints are both Circular and Rectangular. They have been widely used in many installations around the world mostly in Turbine and Condenser applications.

The specialized Dog Bone construction ensures maximum flexibility and operational stability. In- house design capability includes FEA analysis.

This ensures rigid cost effective structural design.

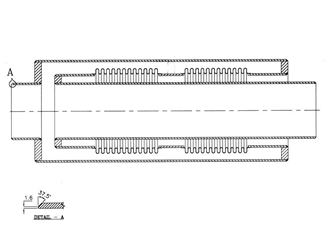

REINFORCED

A Bellows fitted with a member in between its convolutions to reinforce the root of the convolution against internal pressure is termed as Reinforced Bellows.

Reinforcing rings are used if the circumferential stresses become excessive as a result of high operating pressures.

The reinforcing rings absorb circumferential Stresses so that the wall of the Bellows can remain relatively thin and flexible overall.

UN-REINFORCED

A bare Bellows without a Reinforcing member in between its convolutions is termed as Un-reinforced Bellows.

REFRACTORY LINED EXPANSION JOINTS

A Refractory lined expansion joint is an assembly used in a pipe line to allow it to expand and contract as climate conditions move from hot to cold . It ensures that the system remains functional despite the temperatures it is subjected to.

RECTANGLE EXPANSION JOINTS

This type of expansion joint gets its name from the shape of the expansion joints.

LSI-Mech Engineers Pvt. Ltd. has supplied Rectangular Expansion Joints for Surface Condensers, between Turbine Exhaust and Condenser. More than 90% of Rectangular Expansion Joints for Surface Condensers installed in India are from LSI-Mech Engineers Pvt. Ltd.

In addition to this, we have also supplied larger size Rectangular Expansion Joints for Boiler Flue Gas & Air Ducts.

TOROIDAL EXPANSION JOINTS

Toroidal expansion joint is a metallic assembly that consists of toroidal convolutions. These are circular tubes wrapped around pipe ends or weld ends and have a gap at the inside diameter to allow for axial stroke while absorbing changes in expansion or contraction of the pipe line.

Toroidal expansion joints are designed for high pressure and go beyond the pressure limits of standard 'U' shaped convolutions for improved control, quality and flexibility.