BELLOWS TYPE EXPANSION JOINT

Any device containing one or more Bellows (a flexible, corrugated member) with End Connections

BELLOW ELEMENT

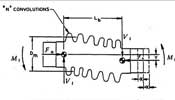

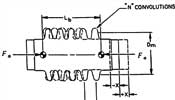

A flexible element, having one or more corrugations / convolutions and end tangents with Lb/Db ≤ 3.

The straight un-convoluted portion at the end of the Bellows is termed as tangent.

FUNCTION OF EXPANSION JOINTS

Why do we require an Expansion Joint ?

Any pipe connecting two points is subjected to numerous types of forces, which result in stresses on its wall.

- Internal or External pressure at working temperature,

- Frequent temperature or pressure changes,

- Movement imposed on pipe section by external restraints, (Eg. the movement of equipment connected rigidly to the pipe),

- Vibration of equipment or structure to which the pipe is connected,

- Thermal expansion

The basic causes of these stresses are:

PRESSURE THRUST

Since a pipe under internal pressure or vacuum will have its wall subjected to circumferential and longitudinal loading, introducing a discontinuous member such as a Bellows will transfer the longitudinal-pressure forces to the main anchors.

Pressure thrust is the product of internal pressure times the Bellows effective area.

The effective area / pressure thrust area of a Bellows is based on the mean diameter of the Bellows convolutions.

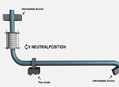

If adequate anchors cannot be provided to absorb the pressure thrust or if connected equipment cannot accept the pressure thrust loading then the joint must be equipped with tie rods. However a tie arrangement equipped Bellows cannot absorb the axial movement.

If proper anchors and guides are not present, the Bellows will deform due to pressure loading leading to total failure.

SPRING RATE

The force required to deflect a Bellows axially.

The spring rate is a function of the dimensions of the Bellows and the material from which it is made.

Movements

AXIAL MOVEMENT

The dimensional shortening of an Expansion Joint due to thermal expansion of pipe and / or dimensional increment due to pipe contraction along its axis.

LATERAL DEFLECTION

The relative displacement two end of the Expansion Joint, perpendicular to its axis due to thermal expansion / contraction of the pipe

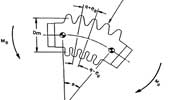

ANGULAR ROTATION

The Rotational displacement of the longitudinal axis from its initial straight line position into a circular arc.

AXIAL MOVEMENT

The dimensional shortening of an Expansion Joint due to thermal expansion of pipe and / or dimensional increment due to pipe contraction along its axis.

ANIMATIONS

Stability

COLUMN INSTABILITY

Column squirm is a gross lateral shift of the centre section of the Bellows. It results in curvature of the Bellows centre line.

IN-PLANE INSTABILITY

In-plane squirm is a shift or rotation of the plane of one or more convolutions such that the plane of these convolutions is no longer perpendicular to the axis of the Bellows.